7 Introduction to Design of Experiments (DoE)

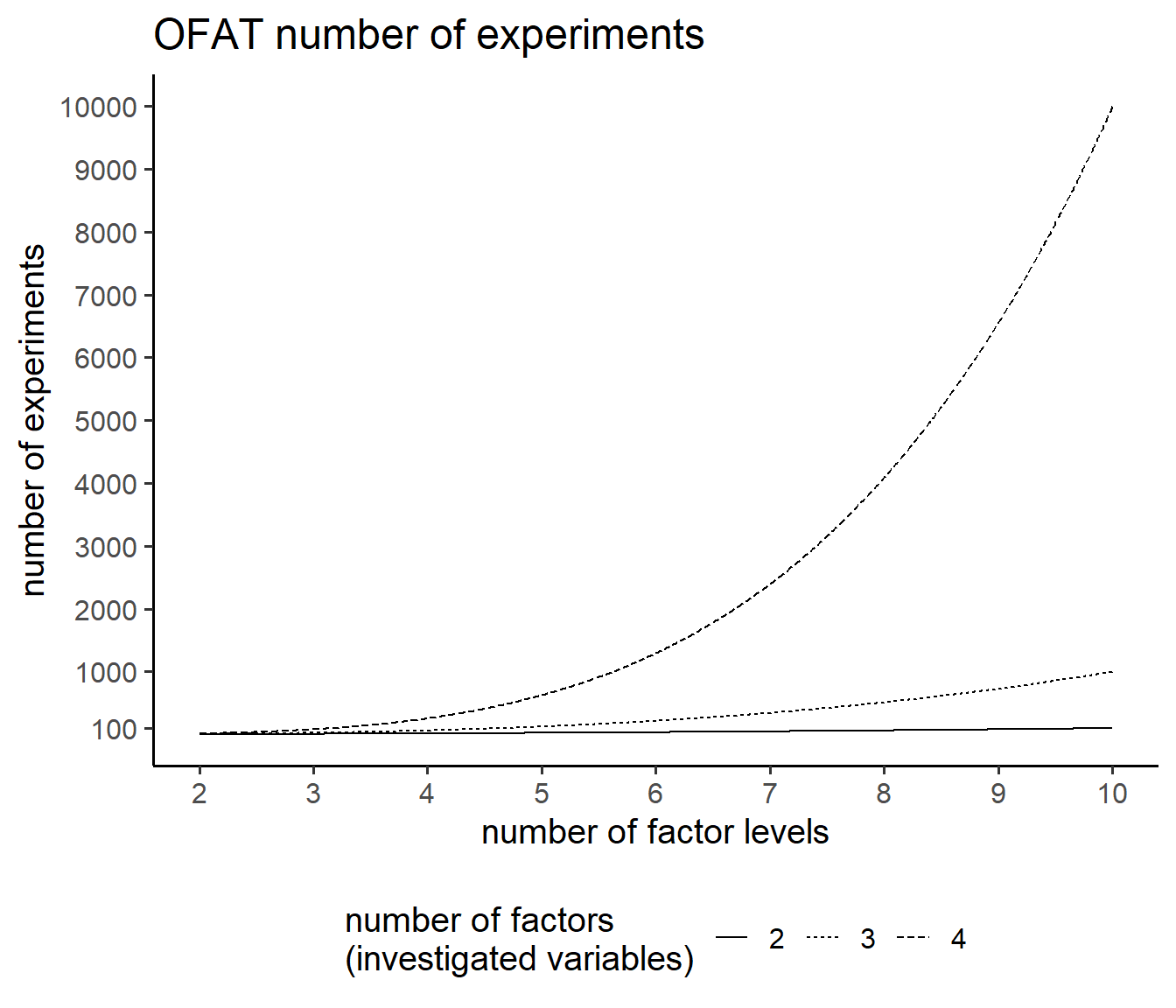

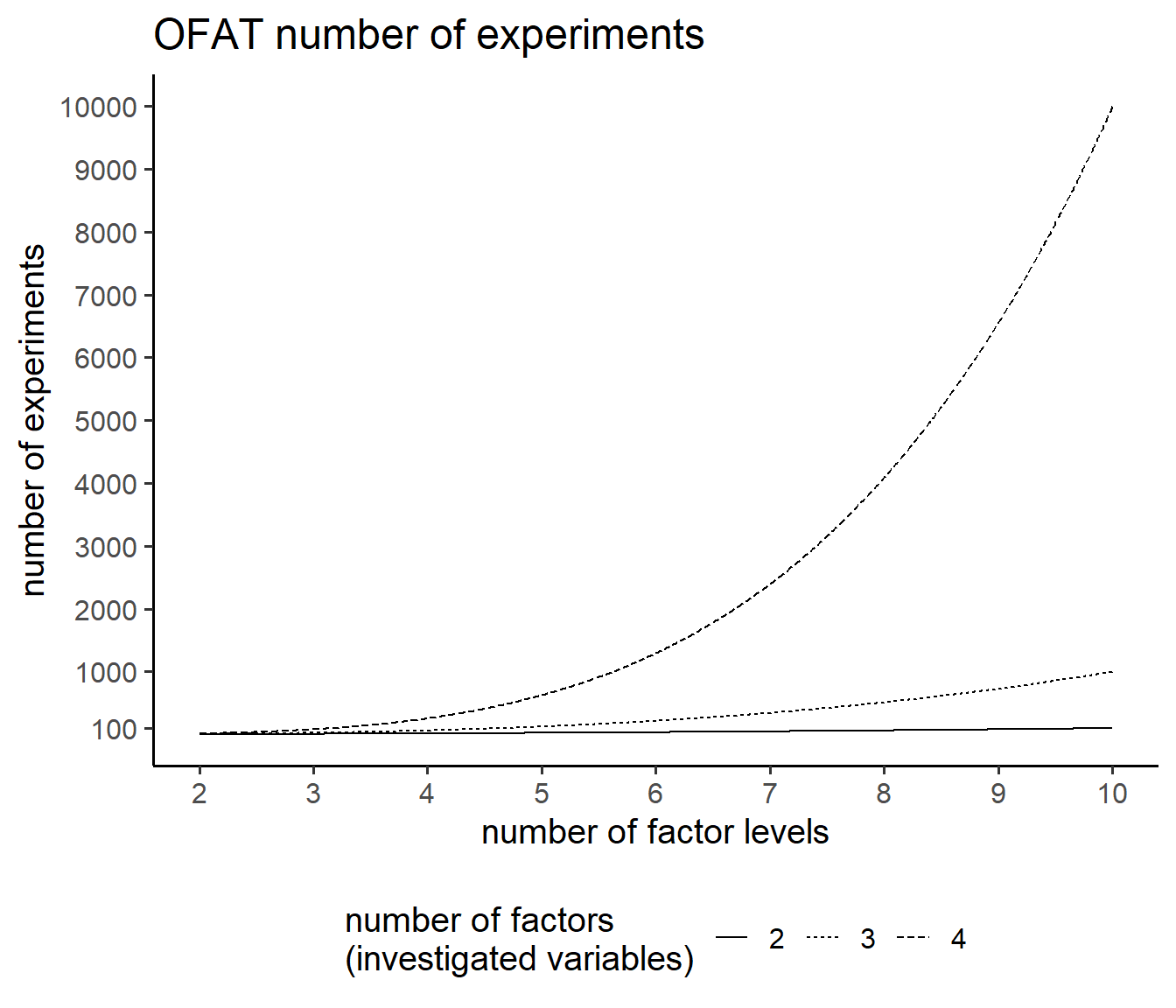

7.1 (O)ne (F)actor (A)t a (T)ime

7.2 curse of dimensionality

\[\begin{align} n_{experiments} = n_{levels}^{n_{factors}} \end{align}\]

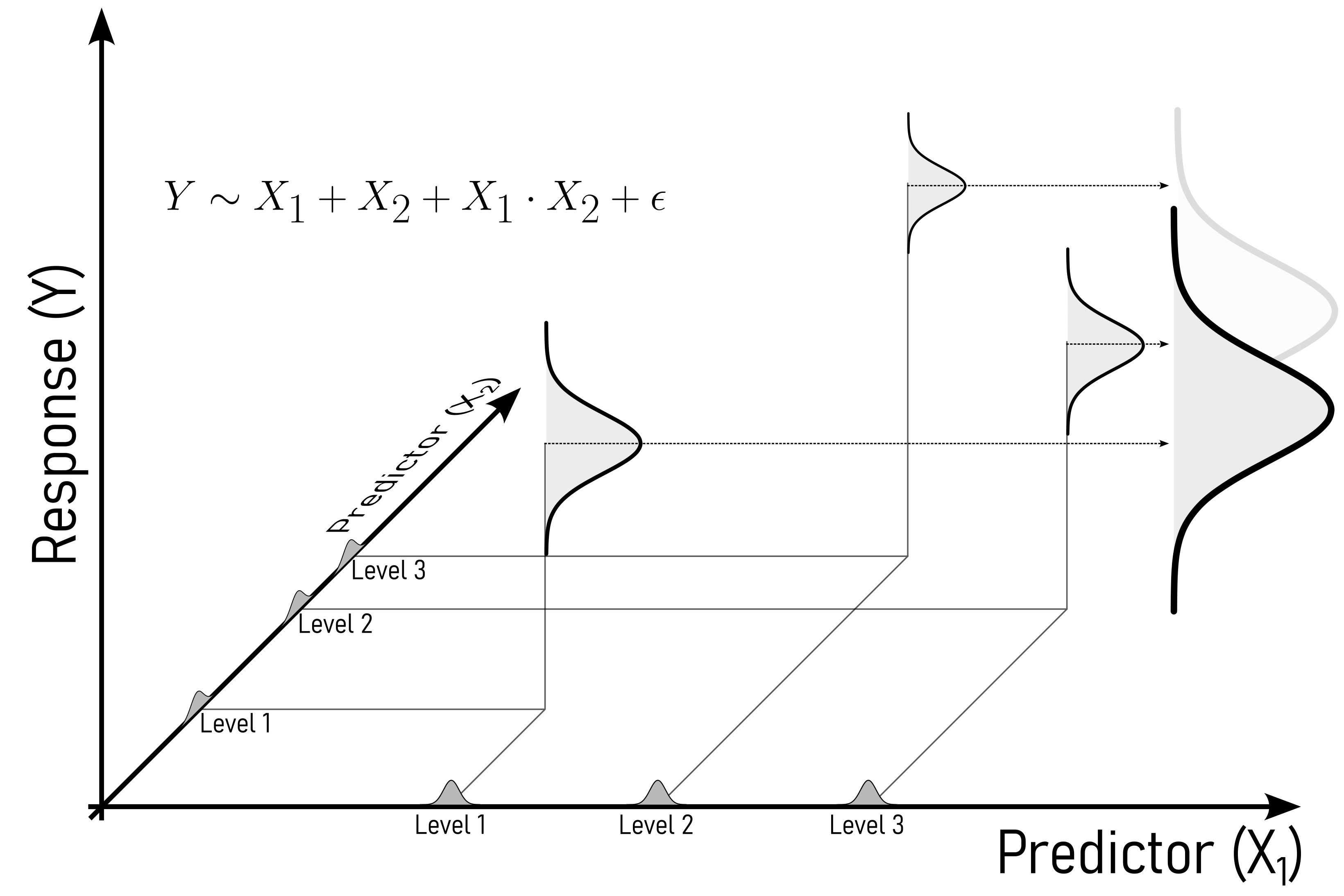

7.3 Concept of ANOVA

7.4 Basics of Experimental Design

7.5 Terminology

- Factors (X’s): Independent variables (e.g., temperature, pressure, catalyst concentration).

- Levels: Values a factor can take (e.g., low/high temperature).

- Response (Y): Dependent variable (e.g., yield, defect rate).

- Treatment: A specific combination of factor levels.

- Replication: Repeating a treatment to estimate error.

- Randomization: Assigning treatments randomly to reduce bias.

- Blocking: Grouping similar experimental units to control nuisance variables.

7.6 Key Concepts

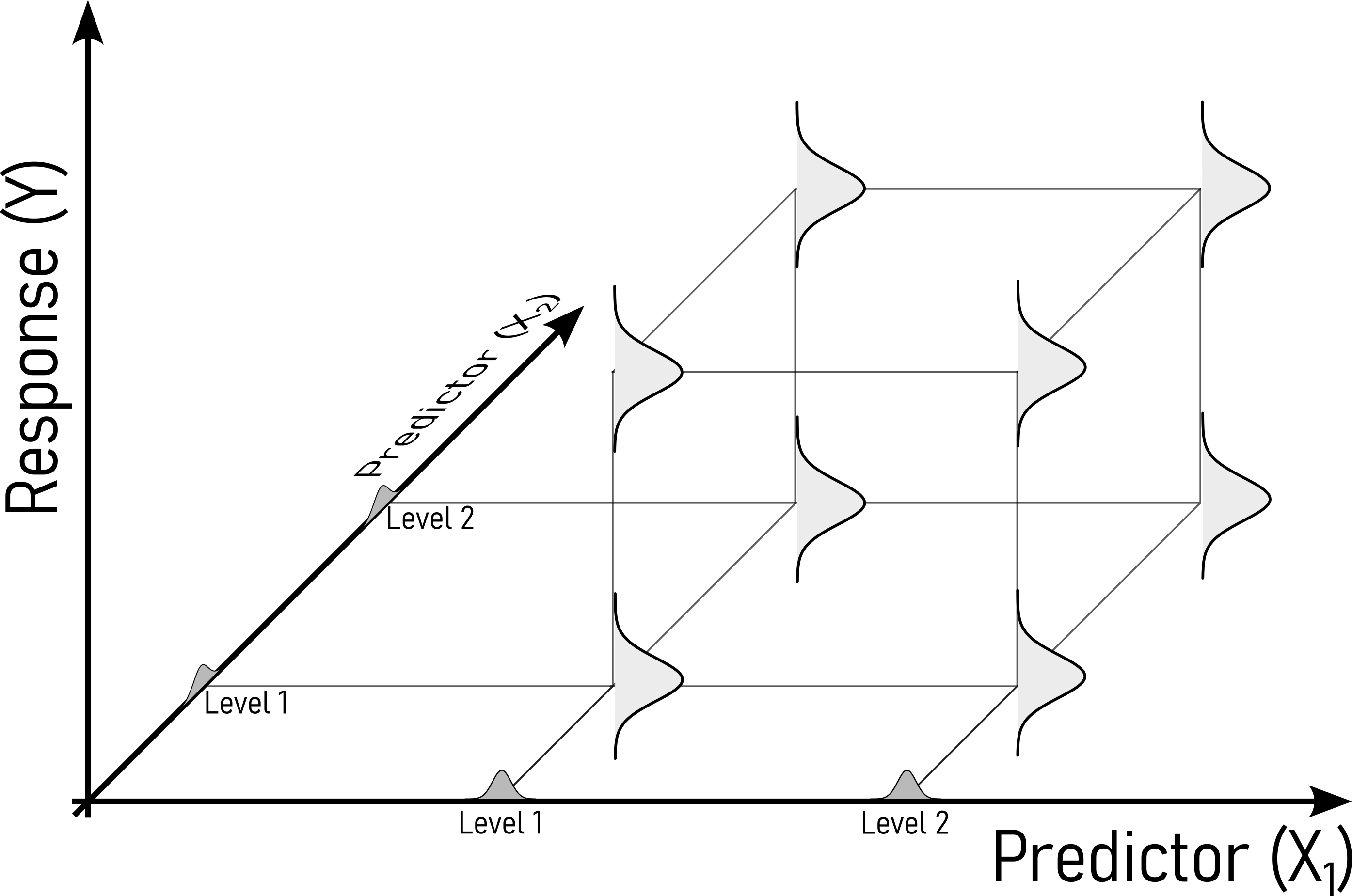

- Factorial Designs: Study all combinations of factor levels (e.g., \(2^2 = 4 \text{runs}\) for \(2\) factors at \(2\) levels).

- Main Effects vs. Interactions:

- Main effect: Change in response due to one factor (e.g., increasing temperature increases yield).

- Interaction: Effect of one factor depends on another (e.g., temperature and pressure interact to affect yield).

- Orthogonality: Factors are uncorrelated (balanced designs).

7.7 DoE Types

7.7.1 Full Factorial

- All possible combinations of factor levels are tested.

- Example: 2 factors (A, B) at 2 levels → 4 runs (\(2^2\)).

- Pros: Estimates all main effects and interactions.

- Cons: Exponential growth in runs (e.g., 5 factors at 2 levels → 32 runs).

7.7.2 Fractional Factorial Designs

- Subset of full factorial runs (e.g., ½ fraction of 2³ = 4 runs instead of 8).

- Trade-off: Some interactions are confounded (aliased) with main effects.

- Use case: Screening many factors to identify important ones.

7.7.3 Response Surface Methodology (RSM)

- Goal: Model curvature (quadratic effects) to find optimal settings.

- Designs: Central Composite Design (CCD), Box-Behnken.

- Example: Optimizing yield by modeling temperature and pressure with quadratic terms.

7.7.4 Taguchi Methods

- Focus: Robustness to noise (e.g., environmental variability).

- Key idea: Use orthogonal arrays to minimize runs.

- Criticism: Less flexible than classical DoE (fixed designs).

7.8 Steps in a DoE

Be bold, but not stupid

7.8.1 Define Objectives

- Screening (identify important factors)?

- Optimization (find best settings)?

- Robustness (reduce variability)?

7.8.2 Select Factors & Levels:

Use subject-matter knowledge or preliminary experiments.

7.8.3 Choose Design

Full/fractional factorial? RSM? Taguchi?

7.8.4 Randomize & Run Experiments:

Avoid bias (e.g., time-order effects).

7.8.5 Analyze Data:

ANOVA, regression, effect plots.

7.8.6 Interpret & Validate:

- Check assumptions (normality, independence).

- Confirm with follow-up experiments.

7.9 Case Study - The catapult

7.9.1 Measurement System

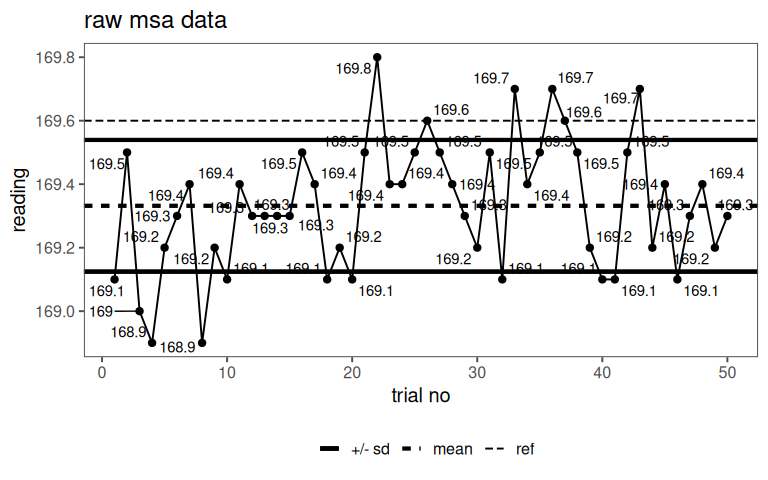

7.9.1.1 raw data

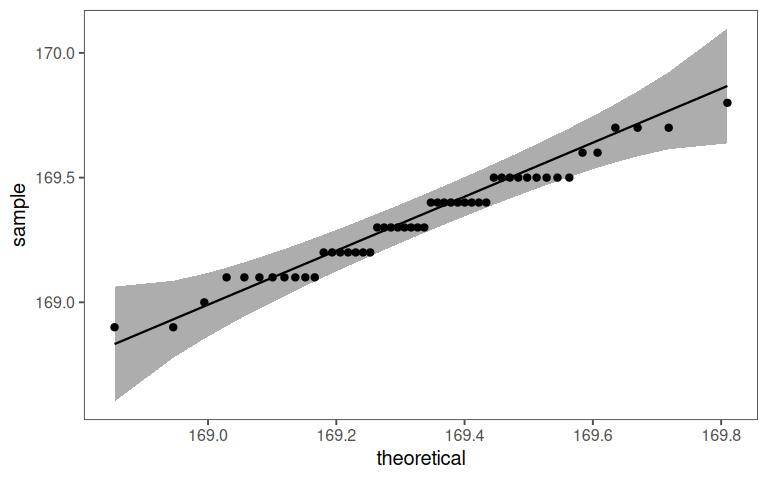

7.9.1.2 distribution

7.9.1.3 possible tolerance window

With a \(C_p = 2\) the tolerance window is \(\pm1.2cm\).

7.9.1.4 systematic error

| .y. | group1 | group2 | n | statistic | df | p |

|---|---|---|---|---|---|---|

| tape_reading_cm | 1 | null model | 50 | -9.134823 | 49 | 3.72e-12 |

With a p-value of 3.72^{-12} there is a significant systematic error.

\[\begin{align} \epsilon_{\text{systematic}} = \text{reference}-\bar{x}_{\text{tape reading}} \end{align}\]

The systematic error is \(0.3cm\).

7.9.1.5 check experiment vs. tolerance window

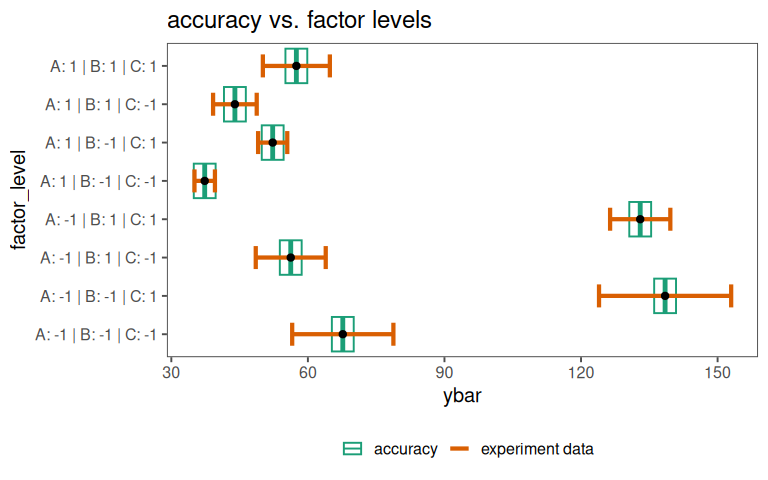

7.9.2 Modeling

7.9.2.1 full model

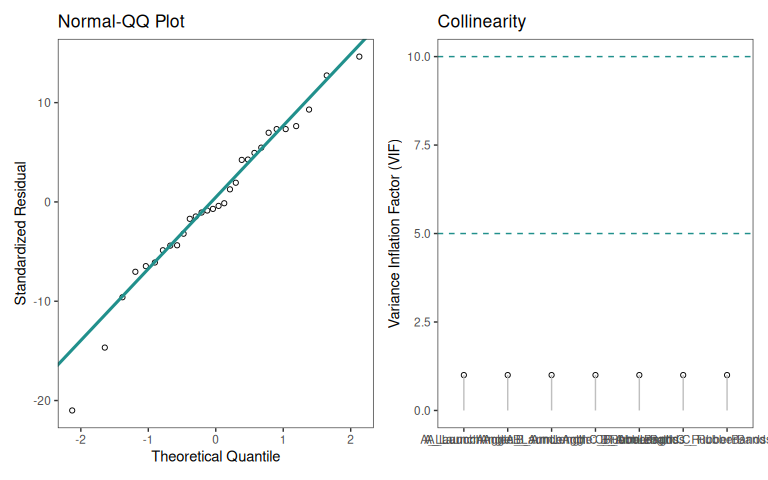

7.9.2.1.1 model quality

7.9.2.1.2 significance

| Characteristic | Beta | 95% CI | p-value | VIF |

|---|---|---|---|---|

| A_LaunchAngle | -26 | -29, -22 | <0.001 | 1.0 |

| B_ArmLength | -0.63 | -4.4, 3.1 | 0.7 | 1.0 |

| C_RubberBands | 22 | 18, 26 | <0.001 | 1.0 |

| A_LaunchAngle * B_ArmLength | 3.6 | -0.16, 7.3 | 0.060 | 1.0 |

| A_LaunchAngle * C_RubberBands | -15 | -19, -11 | <0.001 | 1.0 |

| B_ArmLength * C_RubberBands | 0.57 | -3.2, 4.3 | 0.8 | 1.0 |

| A_LaunchAngle * B_ArmLength * C_RubberBands | -0.93 | -4.7, 2.8 | 0.6 | 1.0 |

| R² | 0.950 | |||

| Adjusted R² | 0.934 | |||

| Abbreviations: CI = Confidence Interval, VIF = Variance Inflation Factor | ||||

7.9.3 DoE - main modeling

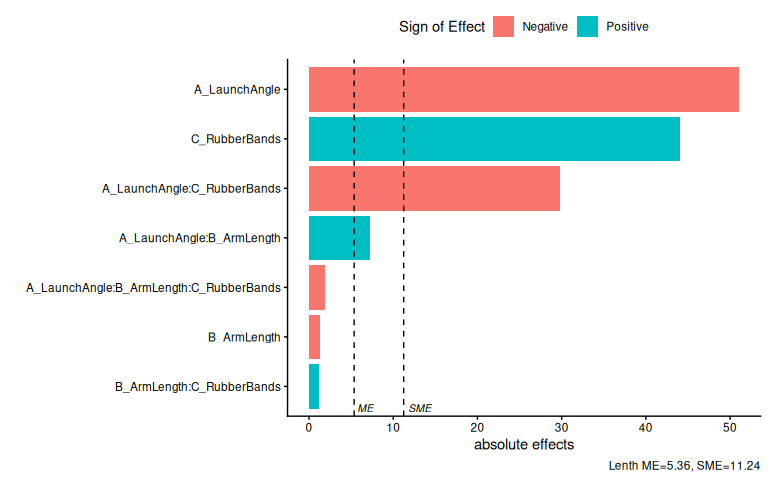

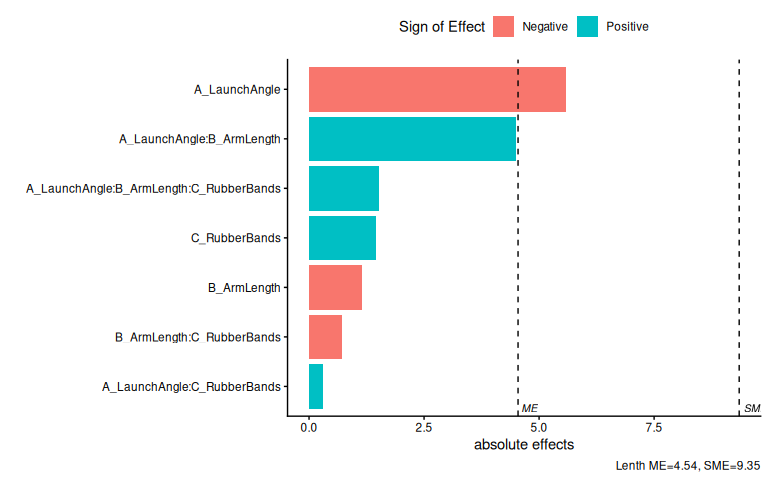

7.9.3.1 pareto plot

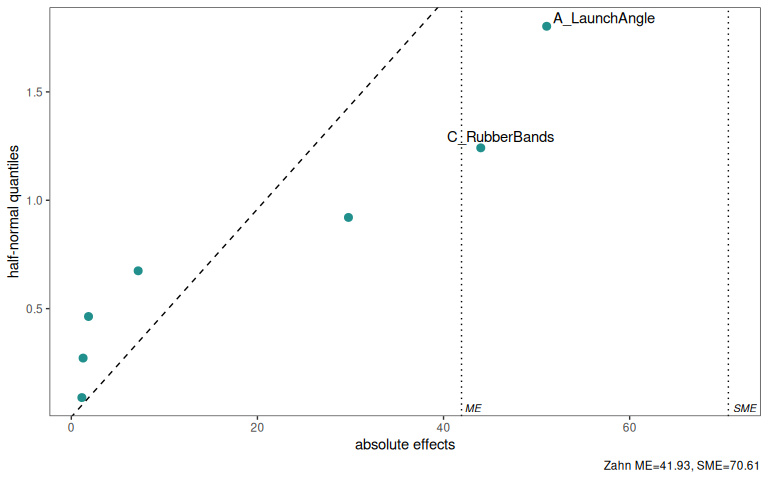

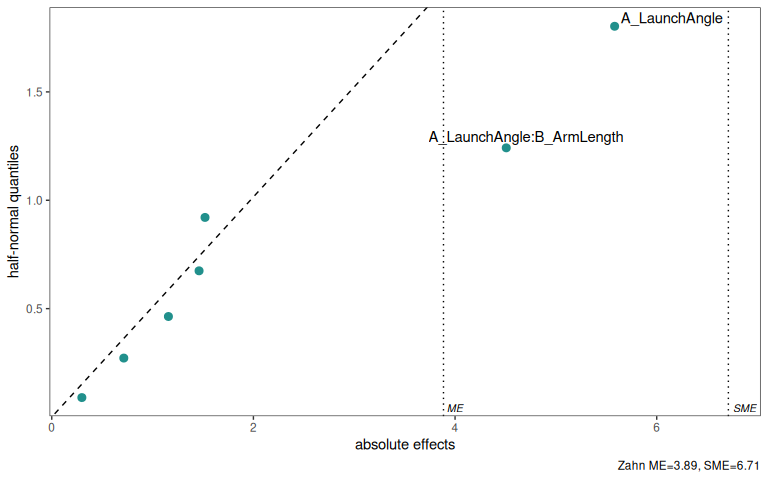

7.9.3.2 half normal plot

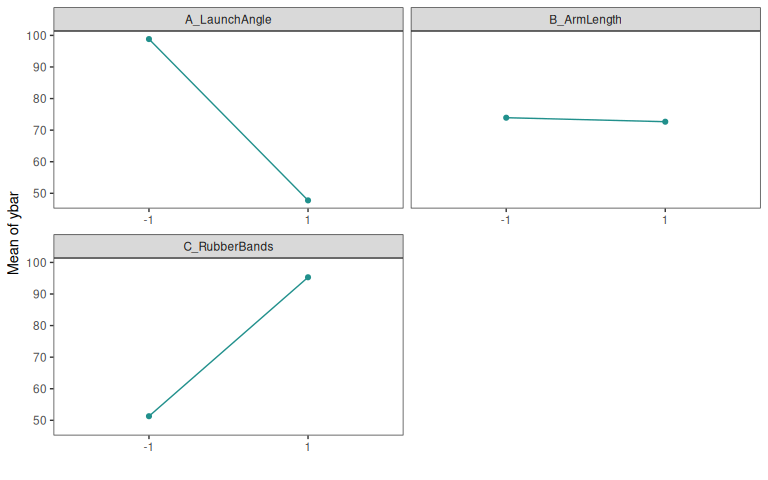

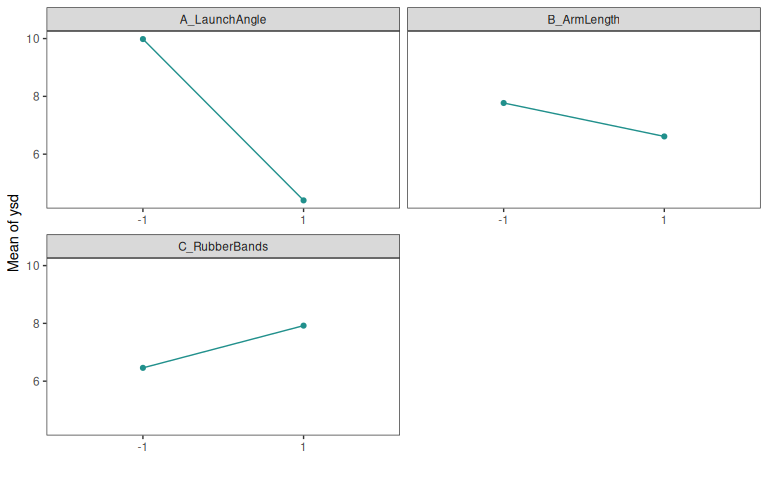

7.9.3.3 Main effect plot

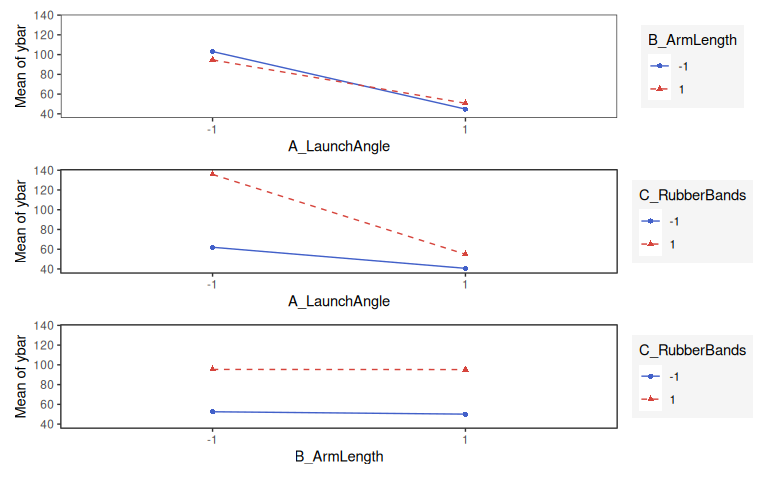

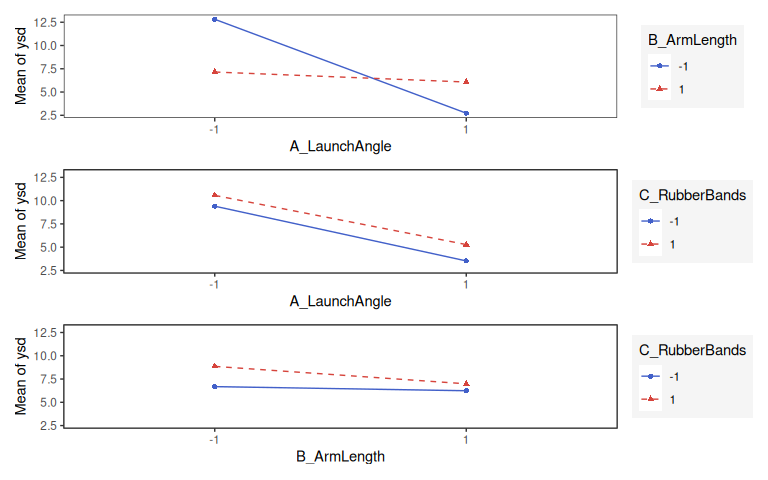

7.9.3.4 Interaction effect plot

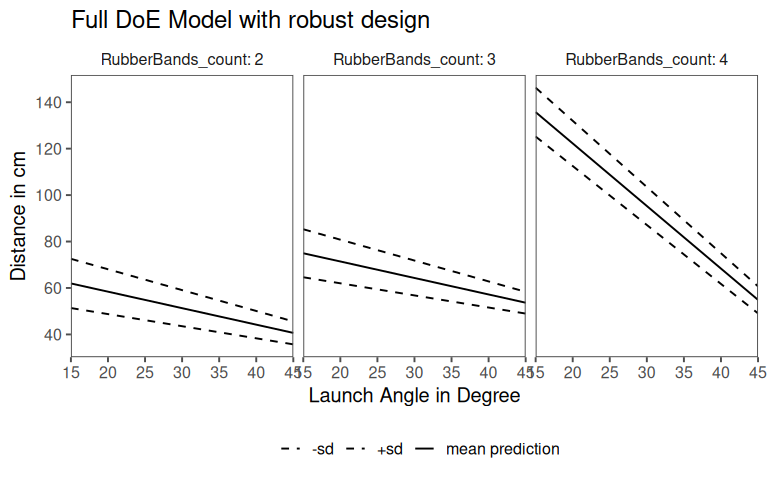

7.9.4 DoE - robust design

7.9.4.1 Pareto plot

7.9.4.2 Half-normal plot

7.9.4.3 Main effect plot

7.9.4.4 Interaction effect plot

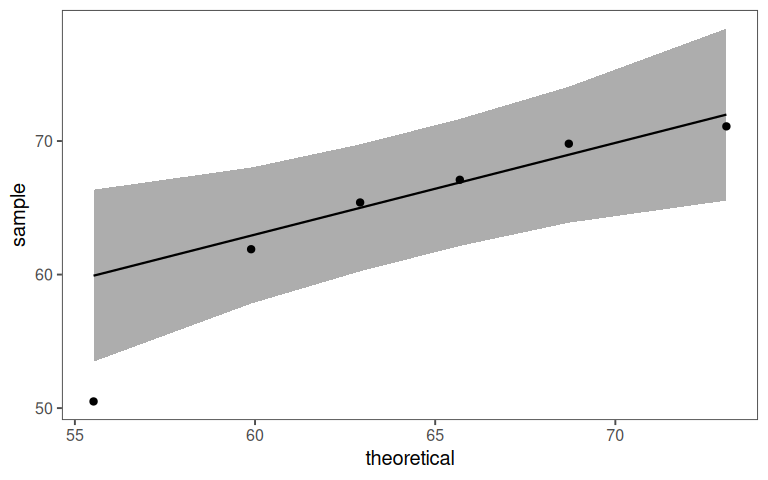

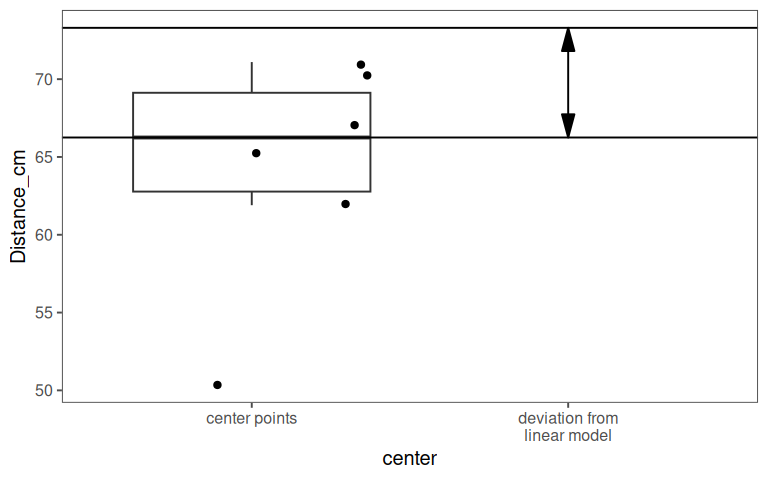

7.9.5 Check for linearity

7.9.5.1 Check center points

7.9.5.2 Test for linear model

With a p value of \(0.032\) the center points deviate significantly from the linear model by about \(9cm\).

7.9.6 DoE - final model

7.9.6.1 Parameters - classic model

| Characteristic | Beta | 95% CI | p-value | VIF |

|---|---|---|---|---|

| A_LaunchAngle | -26 | -31, -20 | <0.001 | 1.0 |

| C_RubberBands | 22 | 17, 27 | <0.001 | 1.0 |

| A_LaunchAngle * C_RubberBands | -15 | -20, -9.6 | 0.001 | 1.0 |

| R² | 0.989 | |||

| Adjusted R² | 0.982 | |||

| Abbreviations: CI = Confidence Interval, VIF = Variance Inflation Factor | ||||

7.9.6.2 Parameters - robust design model

| Characteristic | Beta | 95% CI | p-value | VIF |

|---|---|---|---|---|

| A_LaunchAngle | -2.8 | -4.4, -1.2 | 0.008 | 1.0 |

| B_ArmLength | -0.58 | -2.1, 0.98 | 0.4 | 1.0 |

| A_LaunchAngle * B_ArmLength | 2.3 | 0.69, 3.8 | 0.016 | 1.0 |

| R² | 0.913 | |||

| Adjusted R² | 0.847 | |||

| Abbreviations: CI = Confidence Interval, VIF = Variance Inflation Factor | ||||

7.9.6.3 Final Catapult Model

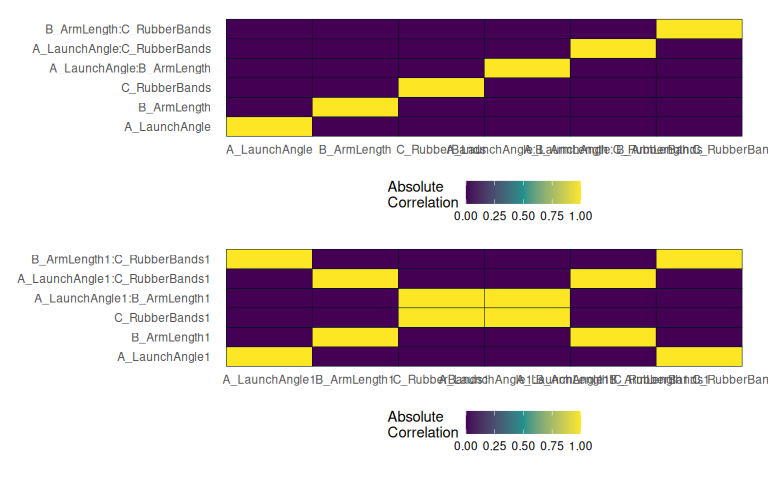

7.9.7 Fractional Factorial (Grömping 2014)

Goal: Identify main effects and key interaction with fewer experiments

7.9.7.1 Experimental plan

Original: \(2^3 \text{(factor levels)}* 3 \text{(repetitions)} + 6\text{(center points)} = 30 \text{ experiments}\)

Fractional (minimal): \(2^{3-1} \text{(factor levels)}* 1 \text{(no repetitions)} + 0\text{(center points)} = 4 \text{ experiments}\)

7.9.7.2 Aliasing

7.9.7.3 Confounding

| A: Launch Angle | B: Arm Length | C: Rubber Bands | A = B:C |

|---|---|---|---|

| -1 | -1 | 1 | -1 |

| 1 | -1 | -1 | 1 |

| -1 | 1 | -1 | -1 |

| 1 | 1 | 1 | 1 |

7.9.7.4 Resolution

- degree of confounding (or aliasing)

- provides a way to classify designs based on how severely factors and interactions are confounded

- Higher resolution means less confounding and more reliable estimation of effects

- III: Main effects are confounded with two-way interactions

- IV: Main effects are confounded with three-way (or higher) interactions, but two-way interactions are confounded with each other

- V: Main effects and two-way interactions are confounded only with three-way (or higher) interactions.

7.9.7.5 practical implications

- Lower resolution (e.g., R-III): Cheaper (fewer runs) but riskier because main effects may be confounded with two-way interactions.

If interactions exist, you might misinterpret the results.

- Higher resolution (e.g., R-V): More expensive (more runs) but provides clearer estimates of main effects and two-way interactions.

Preferred when interactions are suspected or critical.

7.9.7.6 available designs and resoultion